Pennsylvania Furnace, founded in 1813 on the western edge of Ferguson Township, was one of the longest-operating ironworks in Centre County. The furnace survived ownership changes and economic downturns to continue producing pig iron until 1888.

John Lyon built the furnace along a tributary of Spruce Creek to take advantage of the rich iron ore deposit in the area, as well as a large outcropping of limestone. The terrain was ideally suited with the mine, off of present day Diebler Road, and the furnace, along Johnson Road, and the limestone outcropping in between.

Lyon was born in what is now Juniata County in 1782. In 1808, he married Jane Maclay of the prominent William McClay family of Harrisburg. McClay had secured a land warrant in the now Centre Hall area where Lyon and his wife moved and farmed.

Lyon built Pennsylvania Furnace in 1813 in a joint venture with Jacob Haldermann and William Wallace. The furnace had the good fortune of a single iron deposit that provided an almost unlimited source of ore. There was also a large outcropping of limestone for various uses including the construction of ironmaster Lyon’s mansion in 1834. Lyon owned thousands of acres of forests in Ferguson Township and Huntington County, which provided the charcoal for the furnace.

By 1820, the furnace employed about seventy men. A village developed that grew over time to become Pennsylvania Furnace. The market for iron was growing fast in Pittsburgh, but the need was for forged iron rather than pig iron.

To that end John acquired the forges at Coleraine, a few miles downstream along Spruce Creek. In the years to follow, his iron interests expanded to include other forges and iron deposits.

Because of the vast ore pit at Pennsylvania Furnace, the operation was still producing pig iron by 1840, while many other furnaces in Centre County had closed. At that time, the ore washer was invented which allowed ore previously embedded in clay and dirt to be claimed. Pennsylvania Furnace with its single large ore deposit was ideally suited for an ore washer.

An inventive means of providing water to the washer was developed by adding a large dam upstream from the furnace and pumping water through a system of pipes to an aqueduct. The new configuration of mining proved the original furnace to be inadequate and a second much larger furnace, about 43 feet tall, was built 100 feet downstream from the first furnace. This new furnace used the latest technology of the day employing steam for power as well as being converted to hot blast.

As part of expanding his operation, Lyon took on partners, brothers Robert T. and David Stewart, as well as Anthony Shorb. Lyon, Shorb and Company witnessed the successful production of coke from coal, which shifted the use of locally charcoal fired forges to the coal resources of Pittsburgh. Lyon kept pace with that shift and market demands and became active in the iron industry in the Pittsburgh area. He had a second residence in Pittsburgh where he died in 1868.

His company continued to operate and became known to industrialist Andrew Carnegie who took an interest in Pennsylvania Furnace and leased the operation beginning in 1873. Carnegie’s interest in railroads likely had an influence in promoting the western leg of the Lewisburg & Tyrone railroad. That leg was configured to transverse the iron-rich land of Huntingdon County which would then reach Pittsburgh via the existing Pennsylvania Railroad.

Construction began and by 1873, the path had been graded and bridges in place from Tyrone to Pennsylvania Furnace. However, funding problems delayed the rails being in place and trains did not run until 1880.

Once in place, the railroad provided a superior means of transporting ore and pig iron to the modern furnaces in Pittsburgh. By then, Centre Furnace was out of the iron business, so a deal was struck and Carnegie created Scotia. Pennsylvania Furnace ceased operations as the Tyrone Mining and Manufacturing Company in 1888.

A great deal of evidence still exists of the operation at Pennsylvania Furnace, including remains of both stacks. Also visible with the second stack is the stepped retaining walls which provided a shelf that housed the machinery for this then-modern technology furnace. Parts of the base of the ore washer can also be seen, as well as some of the log water pipes used to pump water to the ore washer.

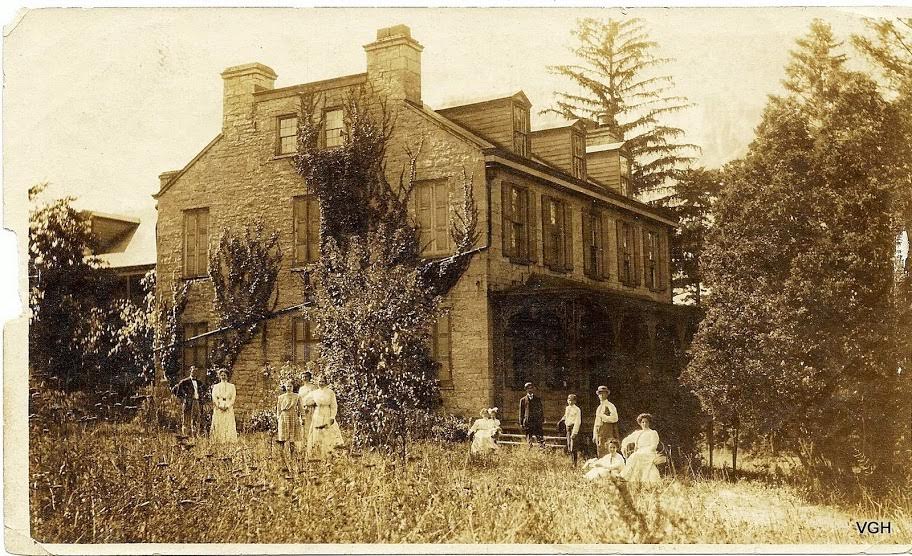

The ironmaster’s home, along Marengo Road in Huntingdon County, is a private residence. It is listed on the National Register of Historic Places.

Bob Hazelton

Sources:

Bining, Arthur Cecil. Pennsylvania Iron Manufacture in the Eighteenth Century. Harrisburg: Pennsylvania Historical Commission, 1938.

Eggert, Gerald G. Making Iron on the Bald Eagle: Roland Curtin’s Ironworks and Workers’ Community. University Park: Penn State University Press, 2000.

National Register of Historic Places, Pennsylvania Furnace Mansion, 1989.

Huntingdon Journal, March 7, 1879.

First Published: September 15, 2021

Last Modified: January 27, 2024