In 1791, Revolutionary War veterans Samuel Miles and John Patton established Centre Furnace and its supporting village in a prime location in the Nittany Valley, an area rich with iron ore. The raw ingredients needed for charcoal iron were iron ore, limestone, and trees for the making of charcoal – the Nittany Valley was rich in all three.

Spring Creek

Centre Furnace – Public – Furnace stack located at the intersection of E. College Ave. and Porter Rd. Read the Centre Furnace Story here. The Mansion is open for tours W/F/Su 1:00 – 4:oo p.m., the grounds/gardens are open dawn to dusk.

Turner Furnace – Daniel Turner established the Turner Iron Works, Spring Creek Forge, and grist and sawmills at the end of the 18rh century, the second industrial operation to be built in what would become Centre County. Turner’s ironmaking property at this industrial site along fast-moving Spring Creek was acquired by Jacob Roop and later Henry Brockerhoff. It became the site of a still standing large brick mill, and a small brewery, the only successful brewery to operate in Centre County in the 19th century, remaining in business until 1902.

Tussey Furnace – This furnace was located near the headwaters of Slab Cabin Run in what is now Pine Grove Mills. While the furnace had a short industrial life, Slab Cabin Run provided the waterpower for a series of gristmills to serve the area’s agricultural needs and gave the community its “mills” label.

Rock – Philip Benner – Public – Less obvious is the site of Philip Benner’s Rock Iron Works, but you can see the Rock (along Rock Road) and the fast-flowing waters of Spring Creek that inspired Benner to settle there.

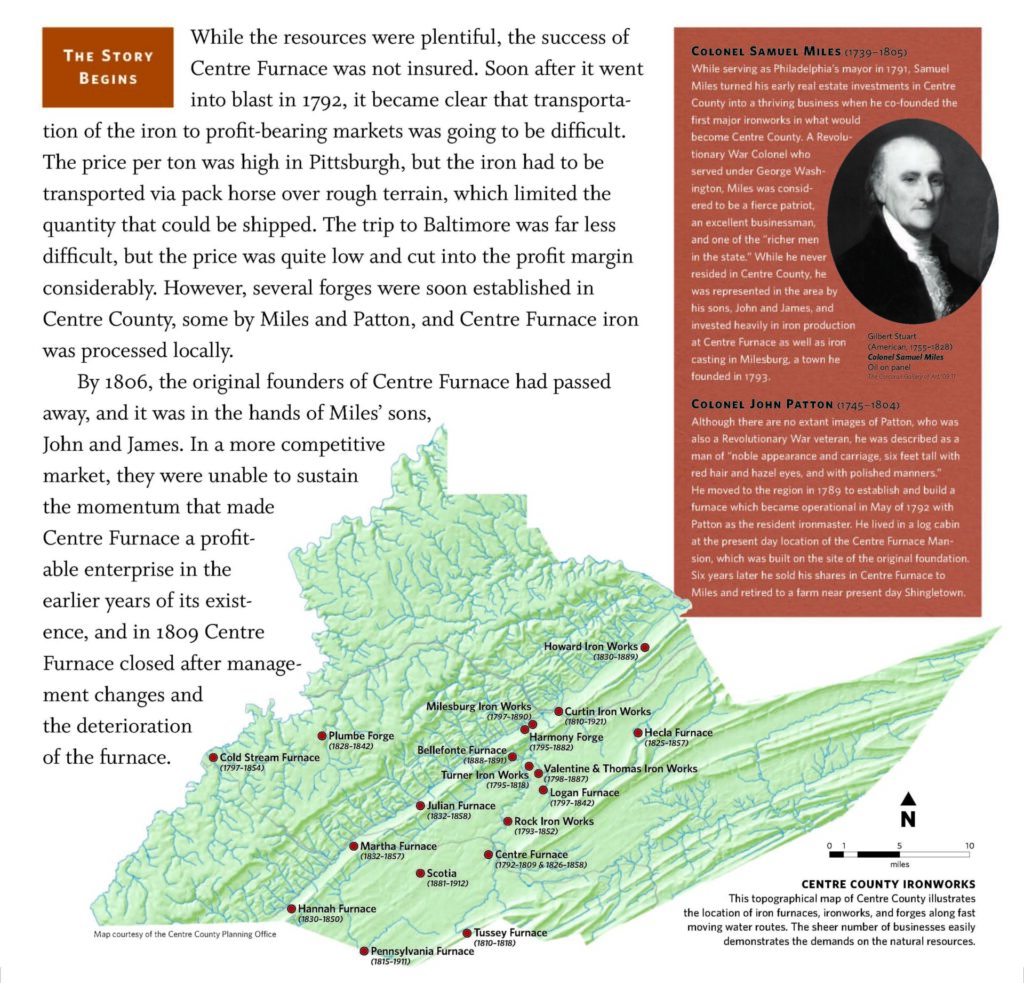

Harmony Forge/Milesburg – Public – The iron forge was constructed in 1795, on property purchased by Colonel Samuel Miles. Construction was supervised by ironmaster John Dunlop and the firm of Miles, Patton and Miles. The construction of the mansion followed sometime thereafter, and can be dated to sometime between 1796 and 1820. Colonel Miles never settled in Centre County, instead sending his sons John and Joseph to manage the forge and lay out the town of “Milesborough”, now Milesburg, circa 1793. It was added to the National Register of Historic Places in 1979.

Logan Furnace – John Dunlop, an ironmaster from Cumberland County, put the Bellefonte Forge into operation on Logan Branch of Spring Creek in 1797 and began construction of Logan Furnace a few miles further downstream. A major figure in early ironmaking, Dunlop also was involved in the building of Harmony Forge at what would become the Milesburg Iron works and Washington Forge in now Clinton County. Early Bellefonte was located on Dunlop’s extensive landholdings by his father, James Dunlop and brother-in-law James Harris. John Dunlop was killed in a mining accident in 1814. His estate was purchased by Bond, Jacob, George, Reuben, and Samuel Valentine, and William A. Thomas, all from Chester County.

Valentine and Thomas Iron Works – In slightly more than a decade the Valentine-Thomas operation encompassing the former Dunlop holdings was producing as much iron as all of the other county furnaces combined. The firm eventually assembled properties – furnaces, forges and ore banks covering almost 6,500 acres and by 1824 operated the county’s first rolling mill with a puddling furnace. The process was cheaper and faster than the old hammer forges. Members of the Valentine family continued with innovations to modernize the manufacture of iron, including the building in 1888 of the hot-blast coke-fueled Bellefonte Furnace, ore-washing methods used at Scotia and elsewhere, and the county’s first artesian well. More information on the Valentine Iron Ore Washing Plant

Bald Eagle Creek

Curtin-Eagle Ironworks – Public – Curtin Village was part of a large iron plantation operated by Roland Curtin and his family from 1810 to 1921. Today, the buildings and grounds are preserved to give visitors historical insights into life as it was in a company town in the 1800s. The site includes the waterwheel-powered Pleasant Furnace and 19th century machines and tools, the Curtin Family Mansion, built in 1830, the workers’ village. The historical site is owned by the Pennsylvania Historical and Museum Commission and managed by the Roland Curtin Foundation. Tours are available on weekends.

Howard – Industrial development on Bald Eagle Creek provided power for the Howard Iron Works and the Howard Brick Company. The creek also provided a location and early access to the Bald Eagle and Spring Creek Navigation Company canal system, in operation by 1837. Most recently the creek provided the water corridor for the John Foster Sayers dam and lake. Of additional significance: Howard resident Bernard Lauth invented and patented the process for cold rolling of iron in 1859, setting the stage for the manufacture of steel. In 1871, he became an owner of the Howard Furnace where he built a rolling mill in 1882.

Julia/Julian Furnace – Built by James Irvin and partner John Adams, it was named to honor Adams’ daughter Julia Ann. The furnace employed from fifty to one hundred men in the various branches including teamsters hauling ore from Buffalo Run Valley, and those engaged in coaling.

Martha Furnace – This furnace was built by Roland Curtin for his son James, and named after his daughter Martha. James Curtin built a large brick home called the Martha Furnace Mansion The furnace employed fifty or more men. However, because of the expense of hauling distant ore and sending pig iron to the forge at Curtin, the manufacture of iron at Martha was not a profitable undertaking to the Curtins. In 1848 the Curtins abandoned the furnace and eventually sold it to Moses Thompson & Co., who put it in blast and operated it until 1855.

Hannah Furnace – This charcoal iron furnace, built along Bald Eagle Creek, was named for Hannah Lloyd, daughter of the senior partner of the firm, Lloyd, Steele and Co. Wood was charcoaled on nearby lands in this heavily forested area, limestone was quarried on Muncy Mountain, and the iron ore was hauled over the mountain from Half Moon Valley.

Philipsburg – Moshannon

Cold Stream Furnace – The making and forging of iron began here at the end of the 18th century when Philipsburg founder Henry Philips began this furnace operation soon after arriving in the area from England. Three years later brother James took over the operation and ran it until 1817, when Cold Stream went out of blast.

Plumbe Forge – Iron production continued in Philipsburg with the opening of Plumbe Forge on Six Mile Run by Hardman Philips, the youngest of the brothers, and family friend Dr. John Plumbe. Pig iron for the forge was hauled over the mountain from Bald Eagle Valley. The forged iron was then hauled to Alexandria and Petersburg in Huntingdon County to be shipped elsewhere on the Pennsylvania Canal. Their most significant effort was the introduction of a screw factory into the operation, the country’s first. Philips and Plumbe recognized the need to find a more efficient and economical method to ship iron, and by the late 1820s began to make plans for construction of what would have been one of the country’s earliest railroads, the Philipsburg and Juniata Railroad Company. They were unable to find local investors, however, and in 1842 the forge closed. Philips and his family returned home to England and Plumbe moved west. Philipsburg’s ironmaking era was over. – A state historical marker notes the former site of Plumbe Forge.

Little Fishing Creek

Hecla Furnace – Built by Isaac McKinney, Hecla Furnace used the water of Little Fishing Creek for power. Its location was near the mouth of a gap through heavily forested Nittany Mountain connecting Penns and Nittany Valleys, and along one of the earliest county roads and an even earlier Indian path named for Mingo Indian Chief Logan.

Spruce Creek

Pennsylvania Furnace – Lyons, Shorb and Co. began charcoal ironmaking at Pennsylvania Furnace in 1810 and continued its operation until 1888. The company held vast landholdings in both Ferguson Township and nearby Huntingdon County, with the stack located on approximately the county line. As with other ironmaking locations, the village of Pennsylvania Furnace grew up around the operation. While little remains of the stack area, the ironmaster’s mansion serves as a prominent reminder of the importance of this industry to central Pennsylvania.

Scotia Iron Mines – Public – Scotia Mines, the first large scale effort iron ore operation begun in 1881, when Andrew Carnegie bought 400 acres from Moses Thompson, four miles northwest of State College, in the area known as the Pine Barrens. Early success dwindled and Carnegie sold the Scotia mining operation in 1899 to the Bellefonte Furnace Company which operated it until 1909. By 1911, Scotia was a ghost town. The Story of Scotia is available from our Museum store.