- Introduction

- Exhibition Panels PDF

- Valentine Ore Washing Plant

- Ore Washing Technology

- Valentine and Thomas Families

- Valentine and Thomas Businesses

- Valentine and Thomas New Ventures

- Ironmaking Heyday

- Credits

Opened in the summer of 2010, the Benner Commerce Park continues the tradition of creating new and better businesses for Centre County. More than a century ago, three generations of an extraordinary family blazed new industrial methods on some of the same land. Hopefully, ideas hatched in the new industrial incubator will be as far reaching, honored and trend-setting as theirs.

Benner Commerce Park sits just off Interstate 99 and state Route 150 in Benner Township. Designed to encompass more than 200 acres, it includes the site of the former Valentine Iron Ore Washing Plant. Valentines and Co. processed ore here in the late 19th century. Archaeological investigations in 2009-2010 located remnants of the ore washing house and its equipment. A Valentine employee drilled Centre County’s first two artesian wells here in 1865.

Methods developed by Abraham S. Valentine in 1842 and used in the old wooden structure are still remembered in history books. Modern manufacturers of mining equipment still employ the same concepts worldwide. Valentine iron won a prestigious award at the nation’s Centennial Exposition celebration in Philadelphia in 1876.

The Valentine Iron Ore Washing Plant

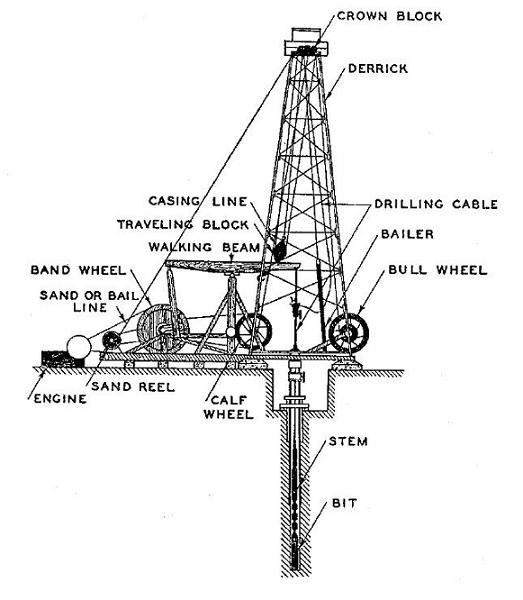

drill for both oil and water

Valentines and Co. operated their iron ore washing plant in the late 1800s. At this site, as it did in its other locations, the company continued to innovate. About 1865, the second generation’s Robert Valentine oversaw the building of a derrick and drilling of two artesian wells, the first in the county. The technology, adapted for the state’s new petroleum industry, sought water, not oil. An independent water source moved ore washers away from shallow streambeds and right to the ore mines, called banks. Robert later said that the plentiful water source more than quadrupled the available ore. E.V. D’Invilliers, who surveyed county mines in 1883, wrote that Valentine ore washing plant wells were 180 feet and 200 feet deep. From them a 50 horsepower motor pumped 180 gallons per minute. D’Invilliers described a wooden structure housing two 25-foot washers that processed 35 to 40 tons of ore daily. The washers used principles developed by first-generation Abraham S. Valentine in 1842 and still used worldwide. Like the wells, this invention made small chunks previously considered waste into a valuable commodity.

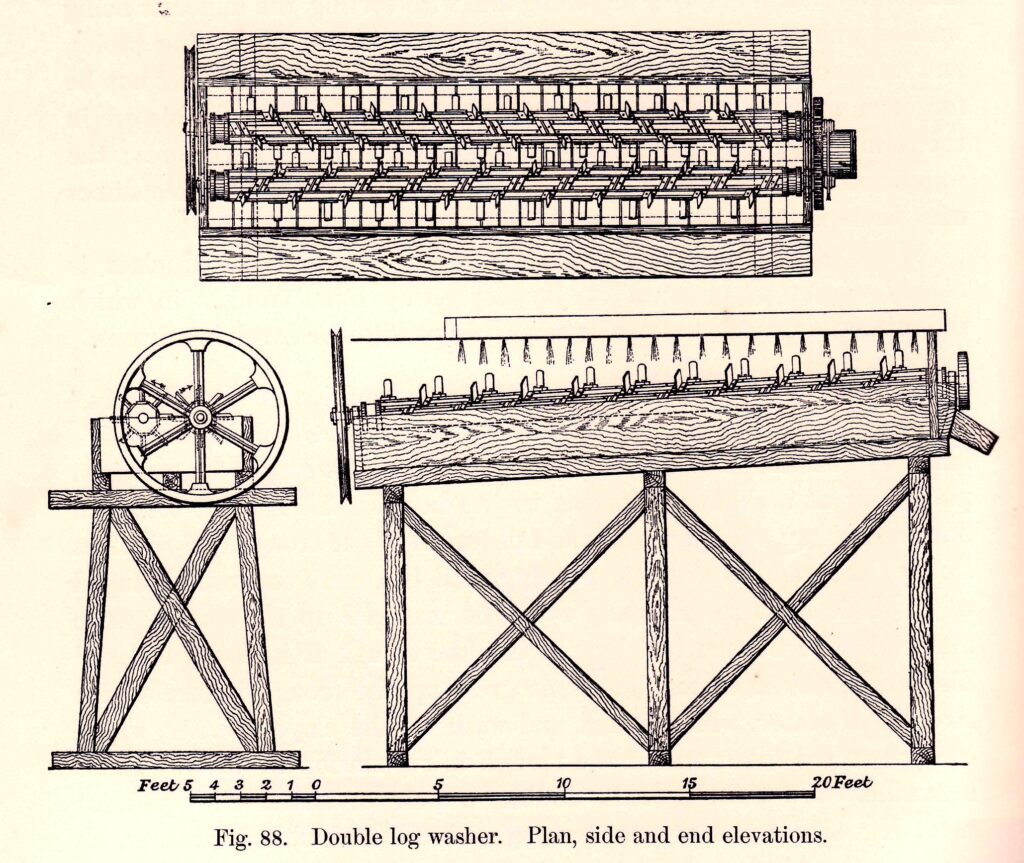

At the Valentine Ore Washing Plant, operated by Abraham S. Valentine’s son Henry from 1887–1898, ore carts were pulled by mule or motor up a long incline and their contents dumped through a grate into a trommel; a rotating screen that size-sorted the materials. The larger ore fragments and rocks dropped onto iron sorting trays or moving conveyor belts from which men and boys picked out impurities. The small ore fragments, flint, and clay fell through the trommel screen into the log washer trough below. Inside the trough, the paddles of the spinning logs beat clay from the ore and flint, which were expelled from its upper end. The cleaned ore and flint then passed through a mechanical jig, which used water-movement to separate the lighter flint from the heavier iron ore. The clean ore was then loaded into carts for transport to the furnace. Local yields were reportedly one ton of clean ore for every three to six cubic yards of earth.

Ore Washer Technology

A significant amount of Centre County iron ore was found in small pieces and embedded in clay. When encountered, it was piled aside to allow the traditional lump ore mining to continue. Several attempts, like the use of the “puddler”, were tried to wash the clay from the ore but were rejected because they were not economically feasible. Abraham S. Valentine’s ore washer invention, in 1842, provided the solution.

Valentine’s design was based on a rotating wooden log with paddles placed in a trough, and with the trough higher at one end. Water was pumped into the trough and on the ore that was to be washed. Rotating paddles pushed the washed ore to the higher end and then out of the washer, ready to be hauled to the furnace. The excess water and clay flowed out the lower end. Usually two logs operated side by side, geared together within the same trough with a steam engine providing the power. Advancement in well drilling to provide the water and in pumping technology allowed the log washer to be operated at the mining site.

Today, ore washers using the same technology are often referred to as log washers, even though the logs have long since been replaced by a steel tube.

Valentine and Thomas Families

The Valentine and Thomas families, cousins of the Quaker faith, settled in Centre County in 1815. The families arrived to begin ironmaking operations near Bellefonte. For the next century, their business decisions would shape Centre County.

The products and innovations they created helped to carve a nation from the wilderness. The impacts of their actions rippled beyond the nation’s borders and even their own era. The forward-thinking Valentines and Thomas built roads and railroads. They played a role in bringing Penn State University to Central Pennsylvania and electricity to Bellefonte 70 years before other rural folks could flip a switch.

Quakers all, they previously made iron in New Jersey and Maryland. They moved from Chester County to Centre County to lease John Dunlop’s Logan Furnace, a year after Dunlop died in a mining accident. Among others, the new arrivals included William A. Thomas and five Valentine brothers – Bond, Jacob, George, Reuben and Samuel. Another Valentine brother, Abraham S., arrived a few years later. William A. Thomas married the Valentines’ niece, Eliza Miller, in 1817, further tightening the family web.

Valentines and Thomas, as the firm was known, leased Logan Furnace, Bellefonte Forge and related ironworks from Dunlop’s estate. Later they leased and then bought Washington Iron Works (a furnace and forge) in Clinton County from Alexander Irvin. Eliza’s brother, Robert Miller, partnered to build a forge at Mill Hall, where the surplus of pig iron from Washington Furnace was converted into wrought iron.

The 1820s were busy ones for Valentines and Thomas. In 1821, the firm bought its rented properties – furnaces, forges and ore banks covering almost 6,500 acres – from the Dunlop estate. By 1824, it operated the county’s first rolling mill with a puddling furnace. The process was cheaper and faster than the old hammer forges.

Valentine and Thomas Businesses

Striving for better ways to reach growing markets in Baltimore, Philadelphia and Pittsburgh, the partners joined companies and commissions. Jacob Valentine became manager of the Kishacoquillas Turnpike Co., which opened a road from Bellefonte to Lewistown in 1822.

Today’s drive from Bellefonte along state Route 144 to Potters Mills and south U.S. Route 322 to Lewistown follows the old cartway. In 1826, Bond Valentine, a lawyer, was among those who convinced the Pennsylvania Legislature to scrap plans to build a canal to Erie in favor of Pittsburgh, where the family kept a marketing agency. The Pennsylvania Canal reached Lewistown in 1830.

During the early 1820s, Bond Valentine, became a founding member of the Agricultural Society of Centre County. Members elected him board secretary and William A. Thomas a director. In 1855, these men aided in convincing the Agricultural Society of Pennsylvania to build its new Farmers High School, now Penn State University, in Centre County. Even the new school’s first president was drawn into the Valentines and Thomas orbit. Evan Pugh married Rebecca, the daughter of Abraham S. Valentine, in 1864.

Much of Centre County’s 19th-century improvements carried a Valentines and Thomas stamp. In 1831, William A. Thomas became chairman of the board of the Bald Eagle and Nittany Valley Turnpike and Railroad. That turnpike ran from Bellefonte to Mill Hall roughly along the present state routes 550 and 64. From Mill Hall, goods could be boated south on the shallow Susquehanna River. During the 1830s Bond Valentine became a commissioner on the Bald Eagle and Spring Creek Navigation Co., chartered to build a canal from Bellefonte to Lock Haven. Not completed until 1848, the waterway washed out in 1866. The first county railroad, the Bellefonte and Snow Shoe, opened in 1859 to carry coal from family mines to that canal.

Other family creations had farther-reaching effects. The firm was involved in patenting a horseshoe nail-making machine and an early railroad car heater. Abraham S. Valentine invented a log washer that separated small pieces of iron ore (previously considered waste) from surrounding clay. Valentine sliced off the edges of large logs, making them polygonal. To these he attached large iron teeth that chewed up the soil and spat out the ore. The teeth could be easily removed, to be replaced or moved to another log. The principle he developed is still used around the world.

Valentine and Thomas New Ventures

As the century progressed, the Valentines and Thomas enterprise added new ventures, some successful and some not.

Valentines and Company, as it was later known, took over the Mann Axe Co., for which Axemann is named. Axes made from Centre County iron carved out the West.

Family members were involved in starting a short-lived glass factory, founding the Undine Fire Co., and running the defunct Bellefonte Republican newspaper.

In 1883, just before the lights dimmed on the family’s fortunes, the second generation’s George Valentine Jr. launched the Edison Illuminating Co. of Bellefonte. He made Bellefonte the second town in the United States to have its own municipal light plant. Congress would not pass the Rural Electrification Act, which carried electric lines beyond metropolitan areas until 1936. Lines would not reach some areas until the late 1950s.

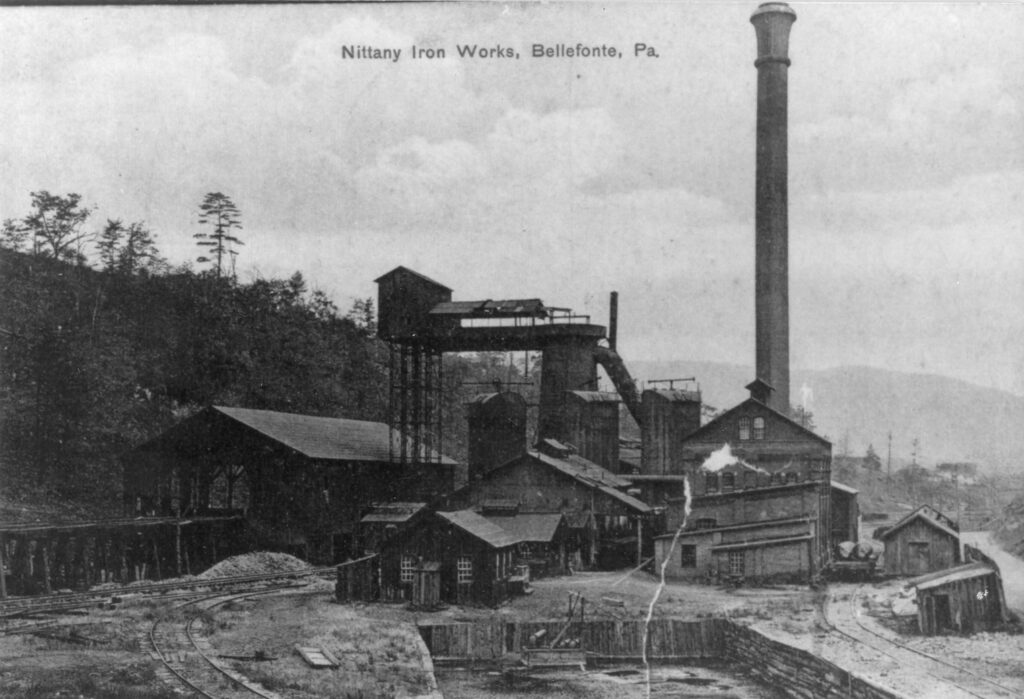

Faced with growing competition from steel plants near major cities, Valentines and Co. found itself in serious financial troubles in the mid 1880s. Family members sold their interests to businessmen from Bellefonte and Philadelphia. The new Centre Iron Co. built a coke-fired Valentine Furnace that some Valentines regained control of in the 1890s. Unfortunately, the continued drop in iron prices, dwindling supplies of local ore and legal wrangling with the Pennsylvania Railroad put the Valentine Iron Co. out of business by 1899.

The last Valentine involved in the family business was Henry Clay Valentine, who served as the superintendent of the Scotia mines for the first decade of 1900s. He died in 1922.

Though the Valentine name was gone, the business they started transformed into one of the county’s major employers during the 20th century. Nittany Iron Works, built from the ashes of the Valentines’ company, became Cerro Metal Products.

Ironmaking Heyday

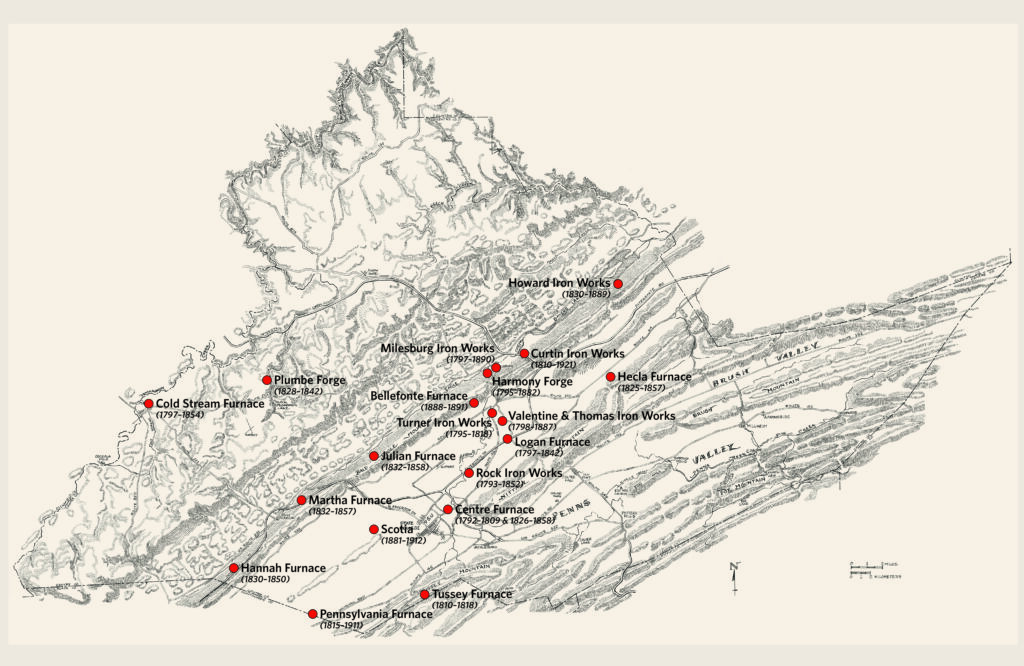

By 1750 Pennsylvania led the colonies in iron manufacturing. Two centuries later, it led the world.

For a 50-year span, beginning in 1800, Centre and four surrounding counties – Blair, Clinton, Huntingdon and Mifflin – remained the nation’s leading iron-producing region. Little more than a decade after the Valentine and Thomas families’ arrival, they proved themselves among the best of the best. During the mid 1820s, they made as much iron at their Logan and Bellefonte furnaces as Centre County’s five other furnaces combined.

The iron produced here became the stuff of everyday life: axes, nails, horseshoes, stoves, door hinges, locks, furniture castors, lamps, clocks, sewing machines and machinery parts. It also became part of government armaments and nation-building railroads.

Then, as now, local manufacturers battled against cheaper imports. Tariffs, or taxes paid on foreign-made goods, protected early American companies. But the rise and fall of domestic iron prices still contributed to furnaces going into “blast” or “blowing out.” The county’s first furnace, Centre Furnace, opened in 1792 and closed when profits fell in 1809. It did not reopen until 1826.

During the 19th century, Centre County iron was made on self-contained “plantations” covering thousands of acres. The Valentines and Thomas firm leased, then bought, roughly 6,500 acres in Patton, Spring and Walker townships from the John Dunlop estate for about $14,500. This gave it ownership of Logan Furnace and Bellefonte Forge in 1827.

On the plantations, brown hematite ore was mined from nearby ore banks. The plantations also contained wash houses to clean the ore, furnaces to melt the iron from the rock and forges to beat the metal into more malleable wrought iron. Those blasting and melting furnaces were usually powered by charcoal made from surrounding virgin forests.

Overseen by ironmasters, the plantations also provided homes, schools, churches, stores and post offices for workers and their families. Large areas of crops were planted to feed people, cattle, horses and mules.

By 1850, federal tariffs had been lowered and the heyday of Central Pennsylvania ironmaking drew to a close. At a convention held in Philadelphia, the Valentines and other ironmasters failed to convince Congress to protect their industry from foreign imports. The Civil War provided some increased demand, but furnace embers grew cold as competition from the state’s newer iron and steel factories rose and federal tariff rates fell even more.

There would be one last hurrah. Charcoal iron proved tougher, more heat-resistant and more malleable than coke iron. Iron products made by Valentines and Co. won a prestigious award in 1876 at the Centennial International Exhibition in Philadelphia. That Centre County continued to make charcoal iron at Curtin Village until 1922 remains a testament to its quality workmanship and reputation.

Credits

Consulting Parties:

Bald Eagle Archaeological Society

Benner Township

Centre County Historical Society

Contributors to the Exhibit:

Bob Donaldson

Mary Alice Graetzer

Sue Hannegan

Bob Hazelton

Jackie Melander

Mary Sorensen

Steve Walton

Kitty Wunderly

Based on archaeological findings and historic research provided to CDICC by:

Heberling Associates, Inc.

Gary Coppock—senior archaeologist and principal investigator

Exhibit Text: Jerilynn Schumacher

Exhibit Design: David Lembeck