The Mann Axe dynasty was founded in 1828 at Boiling Spring, and grew to include five other large operations in central Pennsylvania. Collectively, the companies were among the largest axe makers in the United States and Mann axes were used worldwide.

William Mann Jr., 23, and Harvey Mann, 21, began making axes in 1825 at John Hall’s blacksmith shop in Bellefonte. The two brothers were natives of Johnstown, New York, where their father, William, made edge tools. Three years later, they moved to Boiling Spring (now Axemann) and built a modern forge on property along Logan Branch purchased from Judge Thomas Burnside.

Early axe production was largely a calling of blacksmiths, and the new factory was among the first to employ machinery. Two mill ponds were constructed to provide waterpower for trip hammers. The main building was 350 feet long and 70 feet wide. A finishing plant was later added at Paradise (now Fisherman’s Paradise). Production was carried out by a workforce of fifty men who produced about 350 axes a day. Wages were $2.50 to $3 per day, but that was greater than the $1 wage received by local iron furnace workers.

Axe production in the 1800s was a laborious process, even with the aid of machines. Early axes were made from two pieces of metal. The head of an axe was formed by folding a bar of heated wrought iron which also created an eye. High carbon steel was used for the bit or cutting edge.

Two methods existed for attaching a bit to the iron scarf. An early “inlay” method inserted a bit into a V-shaped cleft or “lip” in the scarf, welded in a forge, and then drawn using a trip hammer. The overlay method — patented by Harvey Mann in 1862 — welded steel on the outside of the scarf, which exposed more steel on the cutting edge. The Axemann factory used coke from Snow Shoe and iron from the Howard Iron Works, as well as steel from Pittsburgh.

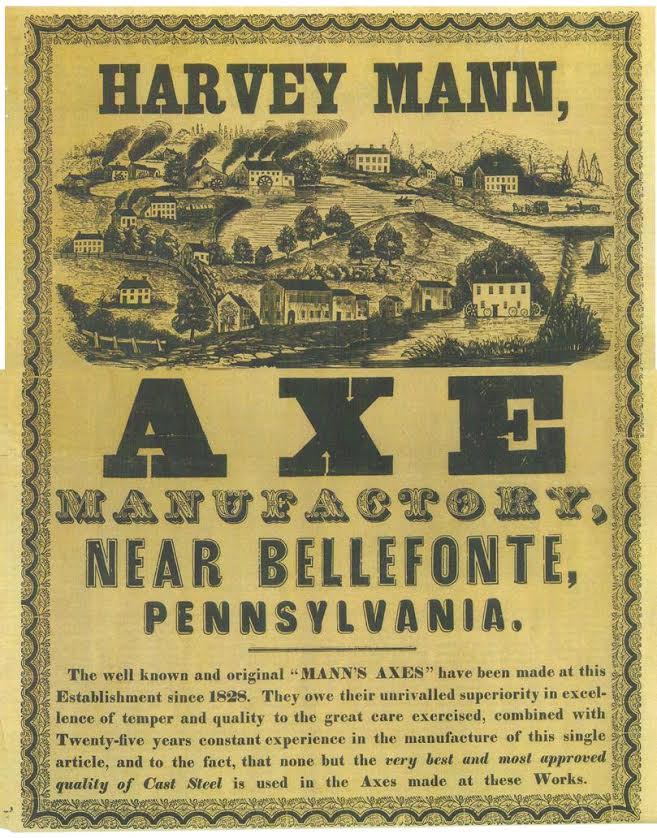

The brothers’ partnership did not survive and in 1834 William sold out to Harvey, who carried on the business as the Harvey Mann Axe Co. Upon Harvey’s death in 1870, he was succeeded by a son, Harvey Jr., but a railroad accident in 1875 resulted in his early death. Robert Mann leased the factory from the widow of Harvey Sr., Jane Burnside Mann. Factory management was transferred to J. Fearon Mann, son of William Jr.

In the 1880s, steam power was added and Fearon patented the “Red Mann Axe.” Prior to this innovation, few companies used proprietary names for axes. Mann axes were promoted heavily with colorful labels and printed advertising.

In 1890 a “monopoly-trust” movement swept the United States and consolidation included the axe industry. American Axe and Tool Co. purchased the Centre County factory, and in October 1892 after 64 years of operation it closed.

Members of the Mann family built axe plants at five other locations near Centre County. In 1835, William Jr. built a large factory in the narrows of Kishacoquillas Creek (now Mann Narrows) near Reedsville. An auxiliary plant operated near Tyrone after 1880. In 1890, the Reedsville factory was purchased by the Axe Trust and it closed in 1903. James Mann made axes in Yeagertown from 1901 to 1923 when the plant was sold to Collins Co.

In 1849, Robert built a large axe factory above Mill Hall on Big Fishing Creek that operated until 1926. A second or lower plant was later devoted to double-bit axes. Finally, Joseph Mann moved to Lewistown and built a factory where Kish Creek empties into the Juniata River. Production at Mann Edge Tool Co. began in 1893. A fire at the Lewistown plant occurred on January 23, 1910. Two days after the fire, the board removed Joseph as president.

By 1920, Mann family members were no longer with the company that carried their name. Along with various ownership and management changes, axes were produced in Lewistown until 2003 when the company was sold to Truper, a Mexican company. The plant was later closed and razed in 2012.

The Mann legacy has outlasted the local manufacturing facility. By the late 1800s, Boiling Spring had grown to the point where it warranted its own post office. There was already another Boiling Springs in Pennsylvania, so the name Axemann was chosen to reflect Mann Axe’s significance.

Other places remain as reminders of the family’s impact on the community. Mann Road crosses the creek opposite the spring. A large stone house, Mann’s Edgefonte, sits near the spring house. Nearby is the United Methodist Church, built in 1882 by Jane Mann as tribute to her late husband. Mann axes remain popular today with collectors.

Jon Nelson

Sources:

Fagley, Paul T. “Man’s second tool: Mann’s first tool. The story of the Mann family and their axe-making dynasty,” Canal History and Technology Proceedings, v16, pp. 1-52, March 1997. Easton, PA: National Canal Museum.

Lamond, Thomas C. “The Mann Axe Making Dynasty and the Mann Edge Tool Co.” Produced and published by the author: Lynbrook, NY, 2012.

Lancaster, Doris E. “The Mann Axe Works: Pioneers build a factory,” Centre Daily Times, September 11-13, 1979.

Magargel, Myrtle.“History of Axemann, Centre Co., PA,” Centre Daily Times, Feb 23-May 7, 1938. http://files.usgwarchives.net/pa/centre/history/local/axem0001.txt (Accessed July 6, 2021).

Pioneer Axe Making at Emerson & Stevens shop, Oakland, ME. Traditional methods in 1965. https://www.youtube.com/watch?v=Qr4VTCwEfko (Accessed July 6, 2021).

Yesteryears Tools. www.yesteryearstools.com/Yesteryears%20Tools/Home.html (Accessed July 6, 2021).

First Published: August 2, 2021

Last Modified: December 5, 2021